|

PF

301

|

|

Forged

steel rolls include work and back-up rolls for

cold rolling. For this purpose, the

state-of-art facilities are employed in

manufacturing these rolls, of which are

steel-making (EAF), refining (ESR or LF/VD)

and forging (3150t hydraulic press) equipment

to produce the high quality forged steel

blanks. As for heat treatment equipment, the

reproducibility of barrel hardness and the

depth of hardness are guaranteed by mean of

the computer control; As for the heat

treatment procedure, we take on the

pre-heat-treatment, the specific

induction-heating quenching (progressive or

integral), the cold treatment and the

tempering, so as to provide the rolls with

high and homogeneous hardness in the work

layer with superior wearability, high

toughness and sufficient resistance to

accident, the depth of hardened layer may be

over 30mm, so when these high quality work

tolls are applied on the modern wide cold

strip mills at home and abroad, the

satisfactory performance have been obtained.

Typical

High Quality Product of Forged Steel Roll -

Cold Strip Mill Rolls:

The

cold strip mill is a modernistic and new type

mills, since the quality requirement of the

strip steel products is very high, then the

strict demands hace been put to the work rolls.

This type of roll manufactured by PFC, such as

the work rolls used on the 1700mm cold strip

mill of Wu han Iron & Steel Corp. more than

1000 pieces have been provided. The practice

proved that it appears a high rolling tonnage

between roll change, lower roll-consumption and

long service life, the reputations have been

gained from users.

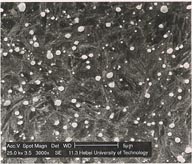

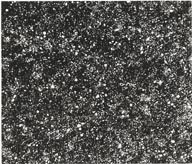

Microstructure:

The

microstructure of barrel surface corresponding

with high and homogeneous hardness, consists of

cryptocrustalline and fine acicular martensite,

fine and uniform carbide and a little of

residual austenite..

|

|

|

|

|

Chemical

composition(%)

|

| Symbol |

C

|

Si

|

Mn

|

Cr

|

Ni

|

Mo

|

v

|

|

| FSC-1 |

0.85-0.95

|

0.25-0.45

|

0.20-0.35

|

1.70-2.10

|

<

0.25

|

0.20-0.40

|

--

|

|

| FSC-2 |

0.80-0.90

|

0.15-0.45

|

0.20-0.55

|

1.80-2.40

|

<

0.25

|

0.20-0.40

|

0.05-0.15

|

|

| FSC-3 |

0.80-0.95

|

0.25-1.00

|

0.20-0.70

|

2.40-3.50

|

<

0.25

|

0.20-1.00

|

0.05-0.15

|

|

| FSC-4 |

0.75-0.95

|

0.20-1.00

|

0.20-0.50

|

2.80-3.60

|

<

0.80

|

0.15-0.40

|

--

|

|

| FSC-5 |

0.60-0.80

|

0.30-0.80

|

0.40-0.90

|

2.50-3.50

|

<

0.80

|

0.20-0.60

|

--

|

|

| FSC-6 |

0.70-0.95

|

0.20-0.90

|

0.20-0.50

|

4.00-6.00

|

<

0.80

|

0.15-1.20

|

<

0.35

|

|

| FSC-7 |

0.80-1.00

|

0.20-0.90

|

0.20-0.40

|

7.50-8.50

|

<

0.80

|

0.25-1.20

|

0.10-0.40

|

|

| FSC-8 |

1.35-1.70

|

<

0.40

|

0.20-0.65

|

11.0-13.0

|

--

|

0.40-1.00

|

0.15-0.30

|

(0.30-0.60)(Co)

|

| FSC-9 |

0.33-0.43

|

0.80-1.20

|

0.20-0.50

|

4.75-5.50

|

--

|

1.10-1.60

|

0.30-0.60

|

|

| FSC-10 |

0.80-0.90

|

<

0.40

|

<

0.40

|

3.80-4.40

|

--

|

4.50-5.50

|

1.75-2.20

|

5.50-6.75(W)

|

| |

|

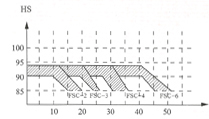

BARREL

HARDNESS (HS)

|

|

FCS-1

|

FCS-2

|

FCS-3

|

FCS-4

|

FCS-5

|

FCS-6

|

FCS-7

|

FCS-8

|

FCS-9

|

FCS-10

|

|

60-70

|

60-80

|

76-80

|

60-80

|

60-70

|

65-75

|

75-85

|

77-85

|

65-71

|

80-95

|

|

90-100

|

90-100

|

90-100

|

90-100

|

65-80

|

90-100

|

90-100

|

86-90

|

75-82

|

--

|

| |

|

HARDNESS

RECOMMENDATION

(HS)

|

|

PROTION

|

APPLICATION

|

HARDNESS

|

| Barrel |

Finishing

work rolls for

strip and plate

mills.

|

90-96

|

|

Cold

work rolls and

temper rolls for

non-ferrous strip,

foil and bright

sheet.

|

>

95

|

| Neck |

Small

diameter cold work

rolls installed with

needle roller

bearing |

>

80

|

| Cold

work rolls with

particular

requirement of

resistance to wear

on bearing portion |

50-70

|

| work

rolls without

special requirement |

30-50

|

|

Note:

Hardness

homogeneity of

barrel is

generally <

3 HS

|

| |

|

HARDENING

DEPTH OF BARREL:

|

|

Diameter

of barrel (mm)

|

>

£X 300

|

£X

301-600

|

£X

601-1020

|

|

Hardening

depth (mm)

|

>

8

|

>

10

|

8-12

|

| The

minimum hardening

depth of work rolls

symbolized with

FSC-1 can be

guaranteed

respectively

according to the

nominal diameter as

the table above, the

hardening depth of

work rolls for other

symbol will be

provided according

to bilateral

agreement. |

| |

|

THE

CAPACITY OF MAKING

|

|

Diameter

of barrel (mm)

|

Length

of barrel (mm)

|

weight

(t)

|

|

£X1020

(Max.)

|

3500

(max.)

|

12

(Max.)

|

| |

| |

|

APPLICATION

OF FORGED STEEL

ROLLS FOR COLD

ROLLING MILLS

|

|

MILL TYPE

|

ROLL TYPE

|

FSC

|

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

|

Rolls for cold

plate and strip

mills

|

|

|

4-Hi mills

|

Work rolls

|

o

|

o

|

o

|

o

|

|

o

|

|

|

|

|

|

Back-up rolls

|

|

o

|

o

|

|

o

|

|

|

|

|

|

|

2-Hi mills

|

Work Rolls

|

o

|

o

|

|

|

|

|

|

|

|

|

|

HC mills

|

Work rolls

|

|

|

|

o

|

|

o

|

|

o

|

|

o

|

|

Intermediate rolls

|

|

o

|

o

|

o

|

o

|

|

|

|

|

|

|

Back-up rolls

|

o

|

o

|

|

|

o

|

|

|

|

|

|

|

Multi-roll mills

|

Work rolls

|

|

|

|

|

|

|

|

|

|

o

|

|

1st intermediate

rolls

|

|

|

|

|

|

|

|

o

|

o

|

|

|

2nd intermediate

rolls (drive)

|

|

|

|

|

|

|

o

|

o

|

o

|

|

|

2nd intermediate

rolls (idler)

|

|

|

|

|

|

|

|

o

|

o

|

|

|

Back-up rolls

|

|

o

|

|

|

|

|

|

|

|

|

|

Non-ferrous mill

rolls

|

|

|

4-Hi mills

|

Work rolls

|

o

|

o

|

o

|

|

|

|

|

|

|

|

|

Back-up rolls

|

o

|

o

|

|

o

|

o

|

|

|

|

|

|

|

2-Hi mills

|

Wrok rolls

|

o

|

o

|

|

|

|

|

|

|

|

|

|

Multi-roll mills

|

Work rolls

|

|

o

|

|

|

|

|

|

|

|

o

|

|

1st intermediate

rolls

|

|

|

|

|

|

|

|

o

|

o

|

|

|

2nd intermediate

rolls (drive)

|

|

|

|

|

|

|

o

|

o

|

o

|

|

|

2nd intermediate

rolls (idler)

|

|

|

|

|

|

|

|

o

|

o

|

|

|

Back-up rolls

|

|

o

|

|

|

|

|

|

|

|

|

|

|

|

xxxx |

xxxx |

xxxx |

xxxx |

xxxx |

xxxx |

xxxx |

xxxx |

xxxx |

xxxx |

|

| |

|

|

|

|