|

PF

104

|

|

High

Ni-Cr duplex indefinite chilled iron rolls

exhibit excellent properties which are produced

by centrifugal or overflow casting process. The

high micro-hardness of matrix and carbide can be

obtained through adjusting the content of Ni,

Cr, Mo and other alloy elements. A fine and

uniform shell layer with a low hardness fall off

can be obtained with special hear treatment

technique. As with a little of graphite, these

rolls are much more resistant to wearing,

firecraking, spalling and pinching.

The

shell depth may be varied to the particular

application, and the core adopts either grey

iron with ductile or nodular iron with high

strength, which can give core and neck a

satisfactory toughness.

The

sufficient cooling water is essential on the

working rolls.

Microstructure:

|

|

|

|

|

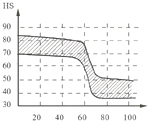

Example of Typical Hardness Profile:

|

| Chemical

Composition (%) |

| Symbol |

C

|

Si

|

Mn

|

Cr

|

Ni

|

Mo

|

| HNiCr-1 |

2.8-3.5

|

0.6-1.1

|

0.4-1.1

|

1.6-2.0

|

4.0-4.5

|

0.2-0.8

|

| HNiCr-2 |

3.0-3.5

|

0.7-1.2

|

0.5-1.2

|

1.4-1.8

|

3.8-4.5

|

0.2-0.8

|

| |

| Physical

Properties: |

| Symbol |

Hardness

HS

|

Tensile

strength

MPa

|

Bending

strength

HS

|

Impact

Value

× 10 4J/m

2

|

Elastic

Modulus

kMPa

|

|

| HNiCr-1 |

70-85

|

350-450

|

450-650

|

3-7

|

150-190

|

| HNiCr-2 |

60-75

|

350-450

|

450-650

|

2-6

|

150-190

|

| Greyy |

35-50

|

>190

|

350

|

3-7

|

110-150

|

| Nodular |

35-50

|

>350

|

350

|

4-7

|

160-190

|

| |

| Application: |

| Work

rolls for finishing final

stands of hot strip mills. |

| Work

rolls for roughing stands

and finishing stands of

wide plate mills. |

| Work

rolls, back-up rolls for

hot strip (plate) temper

mills. |

| Work

rolls for steckel mills. |

| Sleeves

for per-finishing stands

of high-speed wire-rod

mills. |

| Work

rolls for non-ferrous

plate mills. |

| |

| The

Capacity of Making: |

| Methods

of making |

Diameter

of barrel (mm)

|

Length

of barrel (mm)

|

Net

weight

|

|

| |

£X280-1350

|

400-4300

|

45

|

| |

£X800-1300

|

<5500

|

|

|

|

|