|

PF

105

|

|

High Cr duplex rolls use the high alloy cast steel (or iron) with up to 6-22% Cr content as the shell's material, and use high strength nodular iron as the core material.

According to the content of carbon, it can be divided into high Cr cast steel rolls and high Cr cast iron rolls. Influenced by the high Cr content, its carbide is M 7 C 3 which has higher hardness, better toughness and extremely good wear resistance than normal carbide. With the high alloy elements and special heat treatment, the matrix has the excellent comprehensive properties at high temperature.

According to the stand used and cooling water in the hot strip mills, high Cr cast steel or high cast iron can be selected. These rolls can be used as the working rolls in the cold mills and tempering mills, and the rings can also be made of these material..

Microstructure:

|

|

|

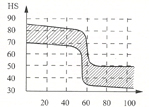

Example

Of typical Hardness Profile. |

|

|

| Chemical

composition(%) |

| Symbol |

C

|

Si

|

Mn

|

Cr

|

Ni

|

Mo

|

| HCr-1 |

2.4-2.8

|

0.4-1.0

|

0.4-1.2

|

10-15

|

0.8-2.0

|

0.7-2.0

|

| HCr-2 |

2.4-3.0

|

0.3-0.8

|

0.5-1.3

|

14-19

|

0.8-2.0

|

0.7-2.0

|

| HCr-3 |

2.5-3.0

|

0.3-0.8

|

0.7-1.5

|

16-21

|

0.8-2.0

|

1.0-1.3

|

| HCrS |

0.6-1.4

|

0.4-1.0

|

02-1.0

|

6-15

|

0.2-1.0

|

1.0-3.0

|

| |

| Physical

Properties: |

| Symbol |

Hardness

HS

|

Tensile

strength

MPa

|

Bending

strength

HS

|

Impact

Value

×10 4J/m

2

|

Elastic

Modulus

kMPa

|

|

| HCr-1 |

60-70

|

500-800

|

700-1000

|

4-8

|

210-225

|

| HCr-2 |

65-80

|

500-800

|

700-1000

|

4-8

|

210-225

|

| HCr-3 |

78-92

|

600-900

|

900-1300

|

4-8

|

210-225

|

| HCrS |

65-85

|

700-1000

|

|

|

210-225

|

| Neck |

35-50

|

>350

|

550

|

4-7

|

160-190

|

| |

| HCr-1 |

Work

rolls for roughing stands of

hot strip mills and wide

plate mills. |

| HCr-2 |

Work

rolls for early finishing

stands of hot strip mills

and rolls for bar, rod mills

and seamless tube

straitening mills. |

| HCr-3 |

Work

rolls for cold strip mills

and tempering mills. |

| HCrS |

Work

rolls for roughing and early

stands of hot strip mills,

for cold strip mills and

plate mills |

| |

| The

capacity of making: |

|

Diameter

of barrel (mm)

|

Length

of barrel (mm)

|

Net

weight (t)

|

|

280-1350

|

400-3100

|

32(max)

|

|

|

|