|

PF

204

|

|

Duplex

cast steel back-up rolls are made with double

poured process with the addition of Ni, Cr, Mo

and adopting special heat treatment the shell

structure is tempered sorbite, bainite and a

small amount of uniformly distributed fine

carbide. The material of core and neck of these

duplex cast steel back-up rolls are of high

quality low carbon steel and low alloy steel.

Therefore it possesses the advantage of high

resistance to wear, sufficient resistance to

spalling and of high toughness.

Microstructure:

|

APPLICATION:

|

|

Duplex

cast steel back-up rolls are suitable

for the roughing and finishing stands of

all types of cold and hot strip mills.

This kind of rolls is also applied in

carious types of plate and heavy plate

mills and Steckel mills. |

|

Microstructure: |

|

The

Microstructure of working layer is:

Temper sorbite

Bainite +Temper sobrite |

|

|

| Symbol |

C

|

Si

|

Mn

|

Cr

|

Ni

|

Mo

|

| DCS-1 |

0.6-1.0

|

0.3-0.8

|

1.4-2.4

|

1.4-2.0

|

0.8-1.2

|

0.2-0.6

|

| DCS-2 |

0.6-1.0

|

0.3-0.8

|

1.4-2.4

|

1.6-2.2

|

0.8-1.2

|

0.2-0.6

|

| DCS-3 |

0.6-1.0

|

0.3-0.8

|

1.4-2.4

|

1.8-2.4

|

0.8-1.2

|

0.2-0.6

|

| DCS-4 |

0.3-0.8

|

0.3-0.8

|

0.4-0.8

|

2.5-3.5

|

0.6-1.2

|

0.4-1.0

|

| |

|

|

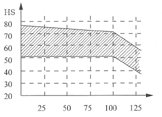

| Symbol |

DCS-1 |

DCS-2 |

DCS-3 |

DCS-4 |

|

| BARREL |

50-60 |

55-65 |

60-70 |

65-75 |

| Neck |

25-45 |

25-45 |

25-45 |

25-45 |

| |

|

|

|

Type

|

Unit

|

Shell

|

Neck

|

|

|

Tensile

Strength

|

MPa

|

1200-2000

|

Min

400

|

|

Yeild

Strength

|

MPa

|

1000-1400

|

Min

200

|

|

Elongation

|

%

|

2-10

|

10-30

|

|

Contraction

|

%

|

--

|

15-40

|

|

Impact

Value

|

kgf.m/cm²

|

Min

7

|

Min

24

|

| |

|

|

|

Diameter

of barrel (mm)

|

Length

of barrel (mm)

|

Net

weight (t)

|

|

£X900-£X1800

|

1000-3200

|

80

|

| |

|

|

|

|