|

PF

205

|

|

High

speed steel (HSS) duplex rolls are manufactured

with vertical centrifugal casting process, the

shell is HSS with high hardness and excellent

wear resistance at high temperature, the core is

nodular cast iron with toughness, the

comprehensive property is a combination of high

wear resistance and toughness.

These

rolls are manufactured with high content alloy

elements and special heat treatment process, the

microstructure of shell is martensite and

bainite with plenty of carbides such as MC, M2C

and M6C distributed among

the matrix, there is only a little hardness drop

in the shell. High alloy elements and

rehardening give the rolls an excellent wear

resistance at high temperature. The outer layer

hardness doesn't show a significant drop until

the temperature exceeds 550C. and the wear

resistance is 3-5 times higher than traditional

high NiCr indefinite chilled iron rolls and high

Cr iron rolls..

Microstructure:

|

| APPLICATION: |

| Work

rolls for finishing stands for hot

strip mills, work rolls for fold

strip mills, rings or sleeves for

bar, rod mills and universal

H-section mills. |

|

|

|

| Microstructure: |

| Martensite

+ Bainite + Carbide |

|

|

|

| Symbol |

C

|

Si

|

Mn

|

Cr

|

Ni

|

Mo

|

v

|

w

|

| HSS-1 |

0.6-1.0

|

0.4-1.5

|

0.4-1.0

|

4.0-8.0

|

0.3-1.5

|

2.0-8.0

|

0.4-2.0

|

1.0-3,0

|

| HSS-2 |

1.5-2.5

|

0.3-1.0

|

0.3-1.5

|

4.0-8.0

|

0.3-1.5

|

2.0-8.0

|

2.0-10.0

|

2.0-10.0

|

| |

|

|

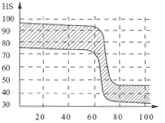

| Symbol |

Hardness

HS

|

Tensile

Strength MPa

|

Elastic

Modulus x 10³ MPA

|

| HSS-1 |

70-90

|

>750

|

210-220

|

| HSS-2 |

75-95

|

>750

|

210-220

|

| Neck |

35-50

|

>350

|

140-180

|

| |

| |

|

|

|

Type

of Rolls

|

Diameter

of barrel (mm)

|

Length

of barrel (mm)

|

weight

(t)

|

|

Rolls

|

£X400-£X850

|

1000-2500

|

15

(Max)

|

|

Sleeves

|

£X200-£X1400

|

700

(Max)

|

7

(Max)

|

| |

|

|

|

|